Breathing Easy: Top Tips for Choosing the Right Fan for Broiler Houses

When you opt for a mechanical ventilation system for your poultry house, the exhaust fans are the driving force to create a comfortable and nurturing environment for the birds. In environmentally controlled houses, where conditions are carefully managed, proper ventilation is not merely an option but an absolute necessity as the health and productivity of your flock depend on it.

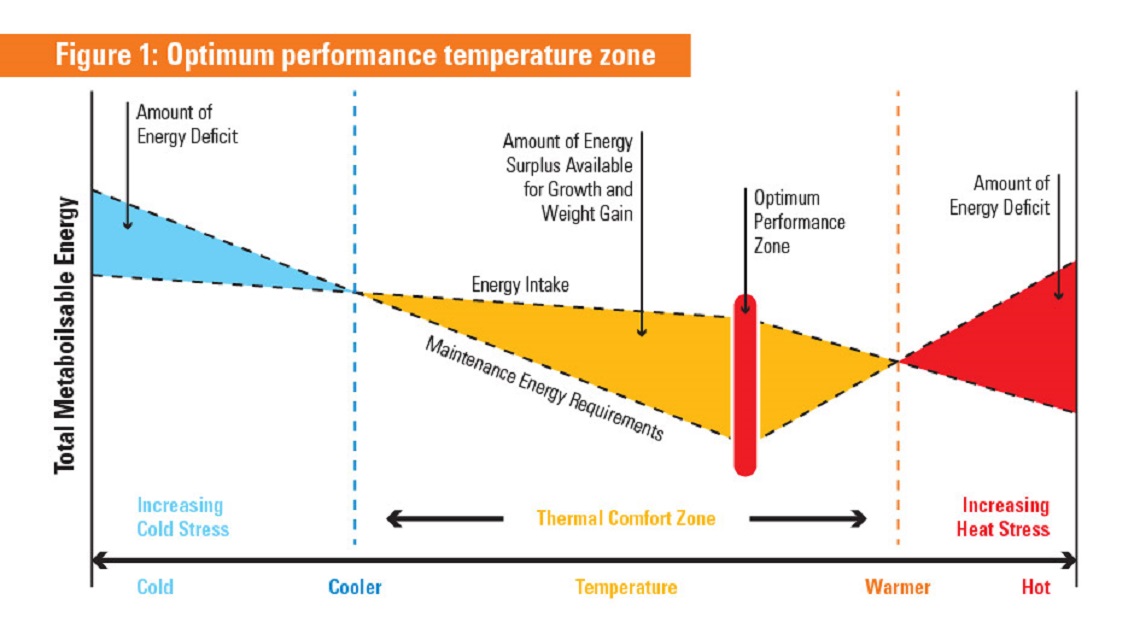

Most modern poultry houses aim to achieve what is called a ‘thermo-neutral zone’, which is an environment that is uniform and balanced. This is achieved by primarily using exhaust fans to maintain optimum air quality, and at the same time remove excess heat, harmful gasses, moisture and dust from the house environment.

By keeping the house condition in a ‘thermo-neutral zone’, birds are more comfortable and perform better with a high feed conversion ratio. In fact, studies indicate that higher temperatures can cause egg size reduction by up to 5 to 7 grams, which impacts the performance of breeder and layer houses significantly.

The 3 Key Considerations:

Choosing the Ideal Fan for Your Environmentally Controlled Houses

Production performance aside, the main objective when choosing a fan is to optimise the farm’s profitability by increasing productivity and reducing operating cost. Experienced producers will know that proper ventilation means they are able to increase the sell amount by ensuring better quality and quantity. In addition, it is also important to understand the costs involved, including the initial investment and operating expenses to help determine future profitability. In essence, there are 3 crucial criteria to closely consider when choosing a fan for your farm:

1. The Economic Factor

To achieve an investment advantage, it simply means purchasing an economical fan with higher air capacity at a low cost or rather considering the 3 performance factors which are: air moving capacity, energy efficiency, and air flow ratio.

Other factors to consider, as follows:

- Determining the total air capacity is needed in the house, based on the following formula:

Total Air Capacity = Nett House Cross Section x Air Speed Desire - Selecting the most ideal fan operating pressure. This element is critical as the longer the house is, the more pressure-sustainable fan that is required.

- Determining the number of fans required involves a calculation as follows:

Total Number of Fans = (Total Air Capacity / Fan Air Capacity @ Fan Operating Pressure) - Analysing the cost per air capacity is also essential as an expensive fan with a bigger air capacity may not always be the most economical option. Equally, a more affordable fan may not provide the air capacity required for optimum performance. Here’s an example of analysing the cost per air capacity:

- Fan A is priced at USD500 and able to generate 50km3/h @ the particular house fan operating pressure and Fan B Price is USD 300 and able to generate 40km3/h @ the particular house fan operating pressure.

- Let’s assume the house requires 200km3/h to achieve the desired air speed, this means 4 units of fan A or 5 units of fan B is required.

- This amounts to a total investment cost of USD2,000 (Fan A) or USD1,500 (Fan B).

- On a cost per air capacity basis, Fan A costs USD 10 per 1km3/h and Fan B costs USD 7.5 per 1km3/h. Thus, Fan B is a better investment choice in this case although it has a lower capacity.

2. Energy Efficiency

Energy efficiency is crucial for reducing operational costs, especially with rising energy costs worldwide. Fans with high efficiency ratings, typically measured in CFM/Watt (cubic feet per minute per watt), means less energy the fan consumes while delivering the desired airflow.

To determine energy efficiency, first understand the power specification of the fan and then calculate power consumption, which is measured in Watt per Air Capacity per Hour (W/1km3/h). Continuing the example above, let’s calculate the power consumption for both fans:

- Fan A generates 50km3/h at the operating pressure, with a power specification of 20W/(1km3/h), which means 1 unit of Fan A consumes 1kW of electricity per hour.

- Meanwhile, Fan B generates 40km3/h at the operating pressure, with a power specification 25W/(1km3/h), which means 1 unit fan B also consumes 1kW electricity per hour.

- While there is no difference in power consumption between both fans, remember that Fan A has a higher air capacity, resulting in reduced number of fans required. As such, using Fan A means the total power consumption is 4kW per hour. Meanwhile, Fan B consumes 5kW per hour, which is 20% higher than Fan A.

- This indicates that power specification is the best unit to standardise the power consumption with the same air capacity.

Of course, there are also other factors that come into play when determining energy efficiency. To be able to justify the return on investment, aspects such as annual fan run time, type of house and local power tariffs are all crucial to ensure an ROI that makes sense.

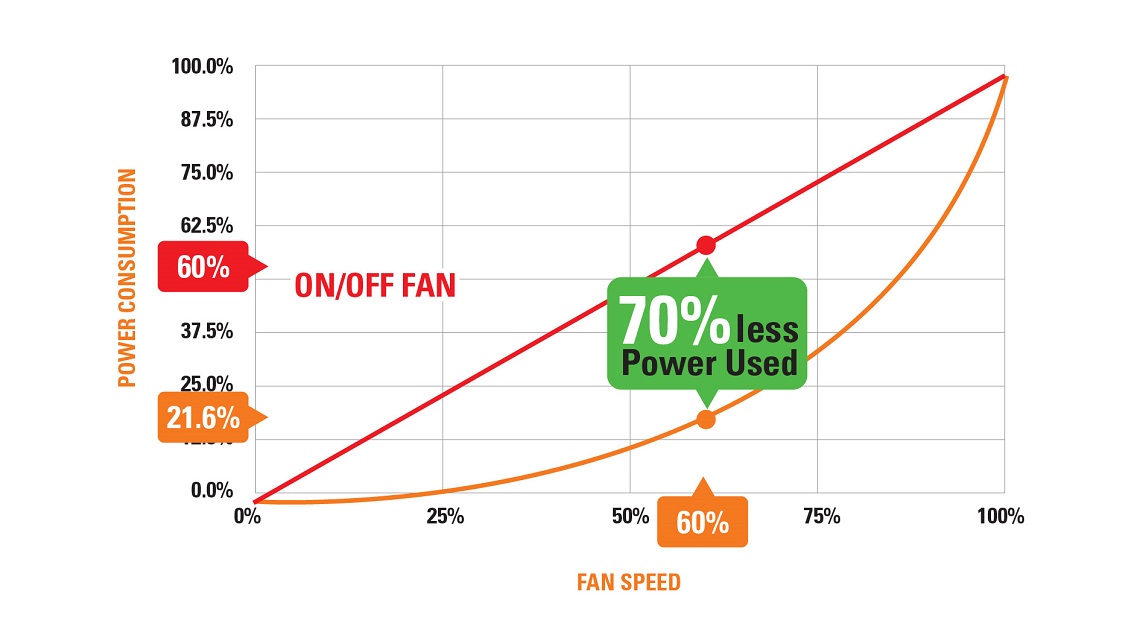

In addition, fans with variable speed control provide flexibility in adjusting airflow based on changing weather conditions and bird requirements. Fans with inverter systems or more energy efficient IE3 motors are also a great choice to keep operational costs low, with up to 70% energy savings.

3. Ease of Maintenance

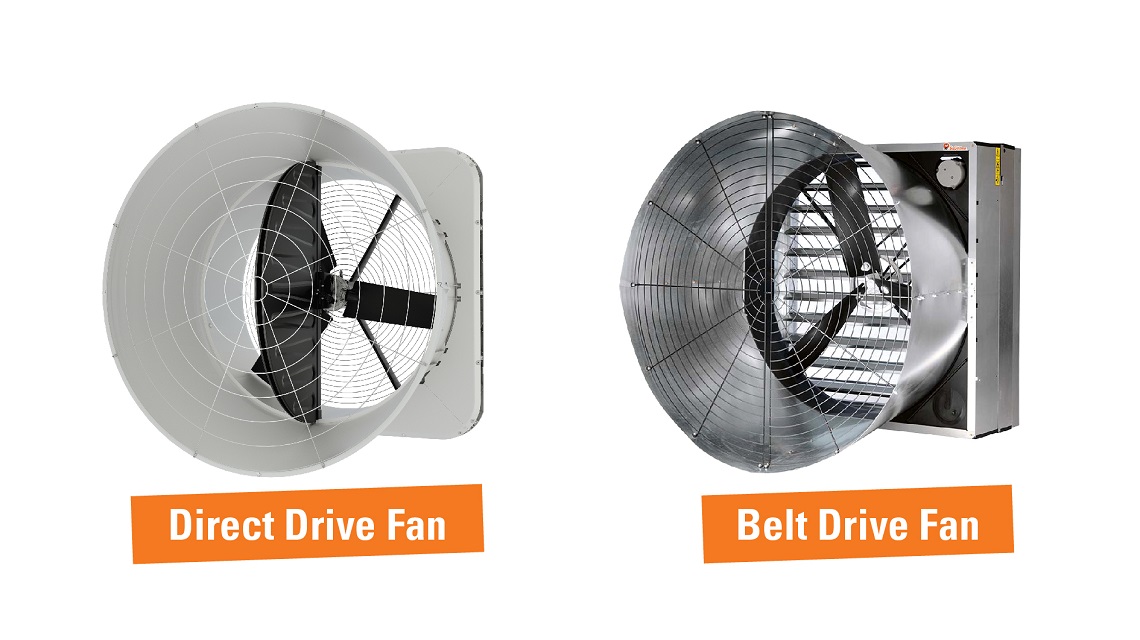

Select fans that are easy to clean and maintain as this contributes significantly to minimising operating costs due to breakdowns and repairs. Features like removable blades and accessible components make regular maintenance more straightforward and contribute to extended fan life. How the fans are driven is also an important consideration, with belt drive fans requiring more maintenance compared to the more robust direct drive fans.

While these 3 key considerations can help with your decision making, there are not exhaustive. Choosing the right fan for your ventilation needs in combination with considerations such as control systems, bird capacity, ventilation type, insulation, cooling equipment and inlets are required to achieve a well-balanced house environment. In fact, comprehensive climate systems for poultry production, including a range of robust exhaust fans with attentive after sales service in Asia is part of Big Dutchman’s core offerings.

We are more than happy to assist your search for the right fan to complement your ventilation needs. Click the ‘Send a Message’ button below to talk to us!