Feed on Farm: Big Dutchman’s Integrated On-Farm Feed Production System

Feed costs account for a significant portion of production expenses in livestock farms — often up to 70% of the total. As such, finding ways to reduce feed costs without compromising quality is essential for egg, poultry or pig producers seeking to remain competitive. One solution that has been gaining traction is the establishment of feed-on-farm facilities. By enabling farmers to produce their own animal feed on-site, these facilities provide substantial cost savings and a range of other benefits.

What is Feed on Farm?

A feed-on-farm facility refers to an on-site setup where farmers can process and produce animal feed. These facilities typically include equipment like grinders, mixers, pelletisers, and storage units. Unlike relying on commercial feed suppliers, farmers using feed-on-farm systems gain the ability to produce feed tailored to their livestock’s specific nutritional requirements, often at a lower cost. This independence reduces reliance on external sources and creates opportunities for better control over feed quality.

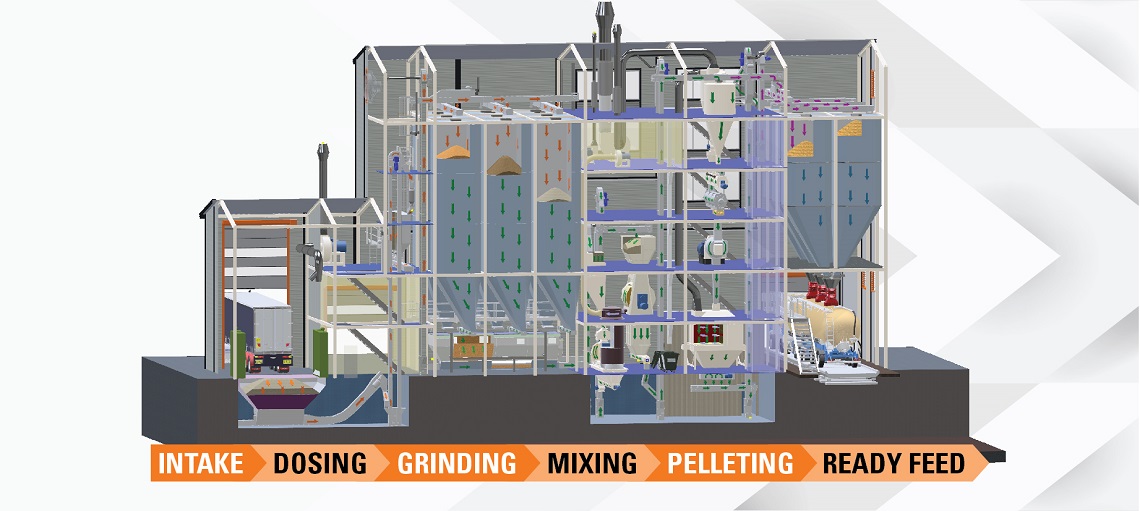

However, traditional on-farm feed milling typically means operating separate equipment manually to produce the desired quantity and quality of feed. This process is quite labour intensive and can pose issues such as contamination, inconsistency and wastage. A far more superior approach will be an integrated On-Farm Feed Milling concept, which in an all-in-one technology that can turn raw ingredients into ready feed in a single process efficiently and quickly.

Empowering Farms with Big Dutchman’s On-Farm Feed Milling

As a result of continuous research, development and engagement with livestock producers the world over, Big Dutchman has created an end-to-end, integrated on-farm feed milling system. As a turnkey solution, this on-farm milling system is virtually automated from start to finish, providing consistently nutritious feed to the exact specifications required.

The system combines dosing, grinding, mixing and pelleting equipment in a fully monitored linear process with high levels of hygiene, automation and processing functionalities. This modular system can be customised to meet your feed management style as all planning, engineering and designing is taken care of by Big Dutchman. Connection to other Big Dutchman equipment such as silos and conveyors is also seamless, while integration to BFN Fusion enables precise monitoring, control and data management.

A Game-changer for Egg, Poultry and Pig Producers

By taking control of feed production, farmers can not only achieve economic stability but also foster healthier, more productive livestock among other advantages. Here are some of the clear-cut advantages of on-farm feed milling:

1. Cost Savings

The potential of significant cost savings is very real with milling feed on farm as farmers are no longer reliant on pre-formulated feed at retail prices, which are all subject to markups in the form of processing, transportation and packaging. Bulk purchasing and local sourcing of ingredients at lower prices also help to drive costs down further.

2. Feed Quality

Another major benefit of the feed-on-farm system is the ability to control the quality of the feed being produced. Feed formulations can be tailored to meet specific needs, while also ensuring that the risk of contamination is minimised. Farmers can also maintain consistent quality, leading to better animal performance.

3. Increased Operational Efficiency

On-farm feed milling helps to streamline farm operations, offering practical benefits such as on-demand feed production, whereby farmers are able to produce exact amount of feed needed, which minimises waste and maintains freshness. And with feed readily available on-site, there are no more issues with delayed delivery.

4. Enhanced Flexibility

On-farm feed milling offers unmatched flexibility for farmers as feed formulations can be swiftly adapted if needed. For instance, when a price of a certain ingredient rises, farmers can adjust formulations to include more cost-effective alternatives. Farmers are also able to experiment with new formulations without committing to large-scale purchases.

5. Better Biosecurity

Commercial feed often passes through multiple stages of processing, packaging, and transportation, increasing the chances of contamination from pathogens. Whereas by producing feed on-site, these external risk factors are minimised, as the entire process is controlled locally and handled under the farmer's supervision.

Many livestock farmers who have adopted feed-on-farm systems report significant benefits. In an industry news portal, Canadian poultry farmers found that bird performance was significantly better with the feed produced on-farm. Improvements in feed conversion ratio and reduced mortality rates were some of the noticeable differences. Even house conditions improved as high-quality feed results in dryer litter, thereby reducing ammonia levels and making the birds more comfortable.

It is clearly evident that feed-on-farm systems offer livestock farmers a powerful tool to reduce costs, enhance feed quality, and improve sustainability.

Want to know more about Big Dutchman’s Feed-on-Farm solution? Click the ‘Send a Message’ Button below to talk to us.