The UNIVENT Advantage: Proven Cage Systems for Starters and Layers

Cage systems for pullets and layers in egg production has undergone tremendous advancements in the last few decades. Especially in Asia, layer farms are increasingly opting for more robust housing systems that improves bird welfare while enhancing performance. These high-quality cages that are built-in with automation systems result in reduced maintenance costs, less reliance of manual labour and increased productivity.

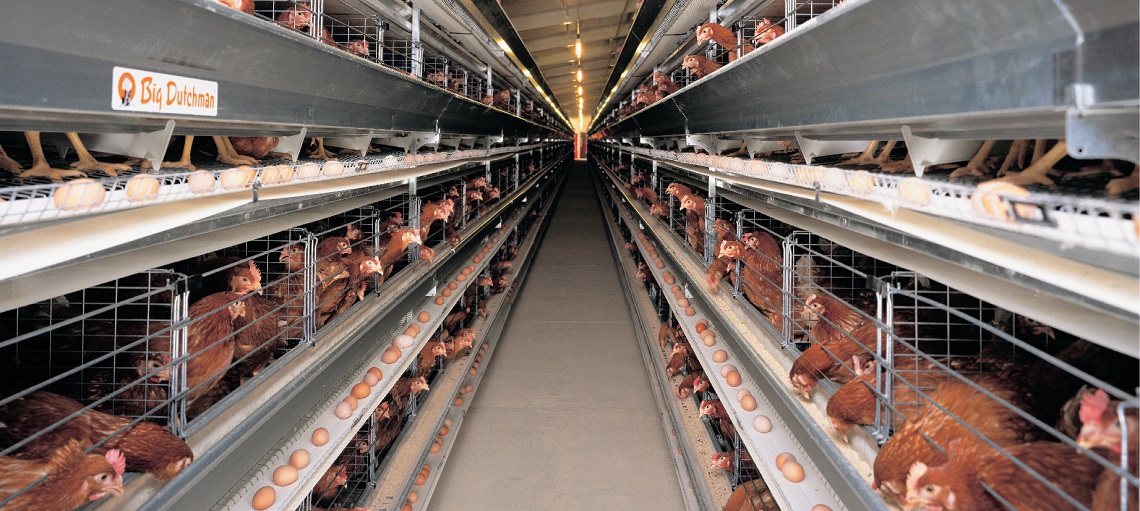

This surging demand for more automated and durable cages has made the UNIVENT layer housing systems from Big Dutchman the ideal choice for modern egg producers. This technically mature system is characterised by a very long service life due to the use of high-quality materials, excellent functional reliability and a high degree of automation. For decades now, UNIVENT cages has been a trademark for quality as an all-inclusive system that takes into account bird health, laying performance and environmental factors.

UNIVENT delivers secure, efficient and successful egg production

While UNIVENT can be configured to many different management styles and farm layouts, there are 3 specific UNIVENT systems that are most popular in Asia:

1. UNIVENT-Starter 680-plus

Specifically used as a rearing cage from 3 to 8 tiers with flexible arrangements to cater for both day-old chicks and pullets. This new and improved model also features a 40mm increase in compartment height that allows for much better air exchange in all tiers of the systems, ensuring pullet uniformity and improved bird welfare. Most importantly, the footrails are made of plastic with no sharp edges or wire ends, ensuring a low injury risk for the young birds.

Learn more about UNIVENT-Starter 680-plus >

2. UNIVENT 600+

Bigger and better than its predecessors with a configuration from 3 to 8 tiers, UNIVENT 600+ features a 50mm increase in the front and rear cage height. This improves ventilation and provides more room for hens to exhibit their natural behaviour such as standing, turning and wing flapping. Automated drinking, feeding and manure management systems come standard while an optional air duct dries manure faster to significantly reduce ammonia emissions.

Learn more about UNIVENT 600+ >

3. UNIVENT 788

As our largest automated battery cage system on offer, UNIVENT 788 is a unique and powerful system with all the necessary features for easy management and simple operation. This system is suited for large layer operations with a vast bird capacity featuring a 2 to 12 tier configuration for a more optimised production footprint. It provides maximum bird comfort and comes with all the feeding, drinking, egg collection and manure removal automations for absolute efficiency.

Learn more about UNIVENT 788 >

All 3 variants of the UNIVENT cages also come with OptiCoat, which is Big Dutchman’s proprietary coating on wire and sheet metal parts to provide 3 to 4 times better corrosion protection compared to galvanised material. This helps ensure long lasting durability in the most demanding environments year after year.

Enhancing the UNIVENT system with ingenious equipment

On its own the UNIVENT cages are already built-in with all the standard automations needed to efficiently operate a layer farm. However, further enhancements in feeding, egg transport, manure management can be made with optional equipment to further optimise and elevate operational performance.

1. Chain Feeding

As a robust feeding system with a long service life, the chain feeder transports feed smoothly to the birds without separating the individual ingredients. It is suitable for any type of feed – be it mash, pellets or crumbles – that can be distributed uniformly and reliably with minimum loss of feed.

2. FC-V Feed Cart

Another automated feed distributor suitable for cage systems consisting of up to 6 tiers without catwalk, and up to 10 tiers with catwalk. It works by a feed cart that is pulled along the entire row providing very even feed distribution so that every hen receives the same quality and quantity of feed.

3. EggScan 120

A simple and easy-to-use egg counter with a high accuracy rate of 99.8%. Featuring a scanning width of 120mm, EggScan 120 accurately records the number of eggs on longitudinal and cross belts. It has an infrared optical technology that works reliably in the dark, along with a protection rating of IP69k for robust performance.

4. AirPaddle

In addition to the air duct, AirPaddle is an alternative equipment for very effective and fast manure drying that significantly help to reduce ammonia emissions. Installed beneath the bird area, and directly above the manure belt, the system consists of multiple paddles that continuously oscillate to generate constant airflow across the entire width of the manure belt.

5. AMBA

To further optimise manure removal, AMBA or Automatic Manure Belt Adjustment ensures the smooth running of the manure belts, which enables manure to be removed more frequently. The system works by using light sensors to ensure the belt is running straight. It does away with the need to adjust the belt manually, hence contributing to more efficient manure removal.

UNIVENT’s standard features, along with multiple enhancement options for both starter and layer operations are proven to optimise productivity, maintain egg quality and improve bird welfare. The system also offer flexibility in configuration and can be adjusted to different flock sizes and production needs, offering a comprehensively smart housing system for high-performing egg production.

Want to take a closer look at the UNIVENT cage system? Click the ‘Send a Message’ Button below to visit us in our showroom.