Optimal Broiler Feeding: Big Dutchman’s Vista 330 Automated Feed Pan

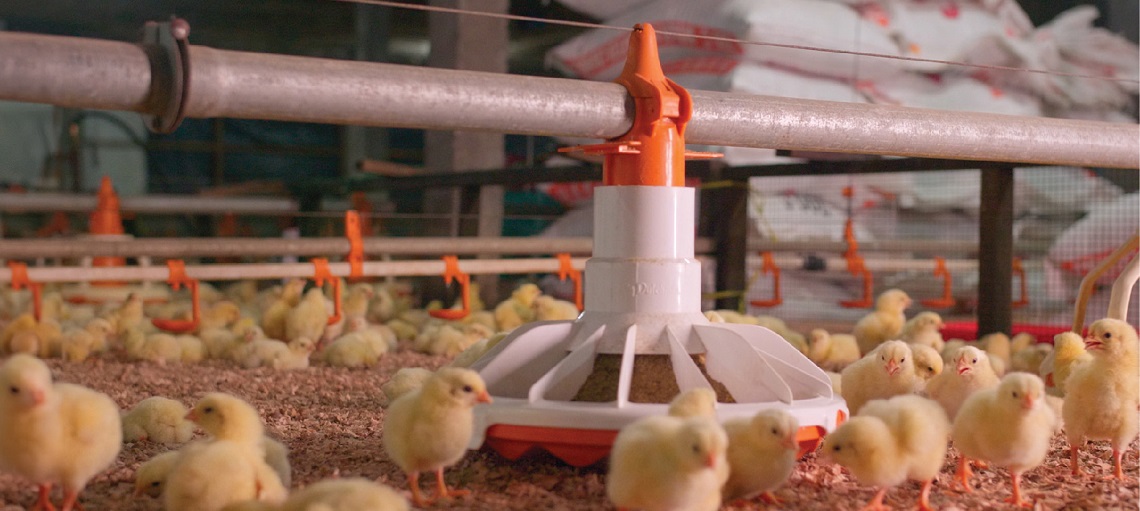

In modern poultry farming, efficient and effective feeding systems are crucial for maximising the growth and productivity of broilers. Broiler chickens are bred specifically for meat production, and their rapid growth rate requires a carefully managed feeding strategy to ensure optimal health and performance. Automated feed pans have emerged as a game-changing technology in broiler production, providing consistent and precise feed delivery from day-old chicks to fully grown broilers.

Nutritional Needs of Broilers

Broilers have specific nutritional needs at different stages of their growth, requiring precise management to ensure they reach their full potential. Proper nutrition is essential not only for weight gain but also for maintaining overall health, supporting immune function, and ensuring the quality of the meat. The key nutrients required by broilers include:

- Protein: Essential for muscle development and growth.

- Energy: Primarily supplied by carbohydrates and fats, necessary for metabolic processes and growth.

- Vitamins and Minerals: Vital for bone development, immune function, and overall health.

Enter Vista 330 – the Innovative Grill-less Feed Pan for Optimal Feeding

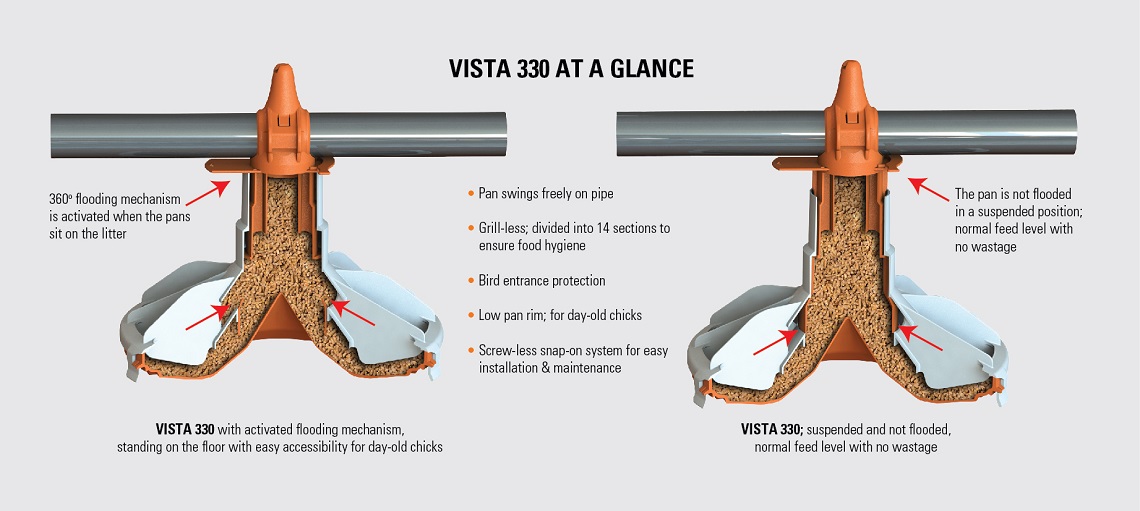

One such innovations is the Vista 330 which is a functional and sturdy feed pan for birds of all ages. This robust feed pan comes without a grilled and is easy to assemble. The pan features a centrally actuated 360-degree flooding mechanism for feed, a globally successful technology by Big Dutchman. This mechanism ensures a high feed level in the pans while they are on the floor during the chicks’ first days. The pans are then lifted depending on the broilers’ age and size, lowering the feed level. Moreover, the grill-less design is especially useful for birds in the final grow-out phase, where they can easily access feed without any breast bruising.

Vista 330 is Enhanced with iDOL29 Sensor

As an added feature, the Vista 330 comes with an integrated LED pan illumination system. This is especially useful as tests have shown that illuminated feed pans attract broilers. Broilers become aware that there is feed still available on illuminated feed pans, resulting in ideal feed provision for the birds.

In modern broiler production, the advantages of Vista 330 become even more apparent, especially since it is able to deliver precise amounts of feed at different stages of broiler growth. Vista 330 is equipped with sensors and automated mechanisms that regulate feed distribution, ensuring that broilers have constant access to fresh feed.

In real-world tests, Vista 330 have proven to enhance broiler feeding to optimum levels:

1. Consistent Feed Delivery

In traditional feeding systems, variations in feed availability can occur due to manual errors or uneven distribution, leading to inconsistencies in growth rates among broilers. Vista 330 feed pans eliminate these issues by ensuring that feed is evenly distributed and always available, promoting uniform growth.

2. Improved Feed Conversion Ratios

Feed conversion ratio (FCR) is a critical metric in broiler production, representing the amount of feed required to produce a certain amount of body weight. Automated feed pans such as Vista 330 optimise FCR by delivering precise amounts of feed tailored to the broilers' growth stage, reducing waste and ensuring that each bird receives the necessary nutrients for efficient growth.

3. Enhanced Animal Welfare

Vista 330 contribute to improved animal welfare by reducing competition for feed. In systems where feed is manually distributed, dominant birds may consume more feed while weaker birds are left with less. Automated systems ensure that all birds have equal access to feed, reducing stress and promoting a healthier, more balanced flock.

4. Labor Efficiency

In addition to their benefits for the birds, Vista 330 feed pans also enhance labour efficiency on the farm. Manual feeding is time-consuming and labour-intensive, requiring workers to monitor feed levels, refill feeders, and ensure even distribution. Automated systems reduce the need for manual intervention, freeing up labour for other essential tasks and reducing the risk of human error.

5. Scalability and Flexibility

The Vista 330 feeding system highly scalable and can be easily adjusted to accommodate different flock sizes and production goals. Whether managing a small-scale operation or a large commercial farm, these systems offer the flexibility to tailor feeding strategies to the specific needs of the operation, ensuring optimal performance at every scale.

From day-old chicks to fully grown broilers, Vista 330 feed pans provide consistent, precise feed delivery that supports optimal health and performance. By reducing waste, improving feed conversion ratios, and promoting uniform growth, Vista 330 a functional and robust addition to any broiler farming operation aiming for success in today's competitive market.

Want to know how Vista 330 can provide optimal feeding for your broilers? Click the ‘Send a Message’ Button below to talk to us.