FAQs: Energy-Efficient Poultry Systems – What Farm Managers Ask Most?

Energy costs represent a critical challenge for Asia's expanding poultry sector. Research shows farm energy usage ranges from 20 to 83 kWh per 1000 pounds of live weight, with the most inefficient operations consuming four times more energy than optimized facilities.

Asia Pacific dominates the global poultry ventilation market, accounting for the largest regional share in 2024. This positioning creates both opportunities and imperatives for energy optimization across the region's rapidly growing production facilities.

Modern integrated solutions can deliver transformative results. Variable speed tunnel fans reduce power usage between 46% and 65% depending on operational conditions, while advanced building technologies achieve up to 85% energy savings compared to traditional poultry houses.

Why Energy Efficiency Matters in Asian Poultry Production

Energy represents approximately 30% of total poultry production costs globally. In Asia's hot, humid climates, this percentage often increases due to intensive cooling and ventilation requirements.

The first step in improving energy efficiency requires knowing how much, where and when energy is used. Research consistently shows that farms without systematic energy management operate at dramatically different efficiency levels.

Asia leads global poultry demand growth, with the market expanding from $384.95 billion in 2024 to $410.98 billion in 2025. This 6.8% compound annual growth rate intensifies pressure on production systems to optimize every operational aspect, particularly energy consumption.

Q1: How do modern ventilation systems reduce energy use?

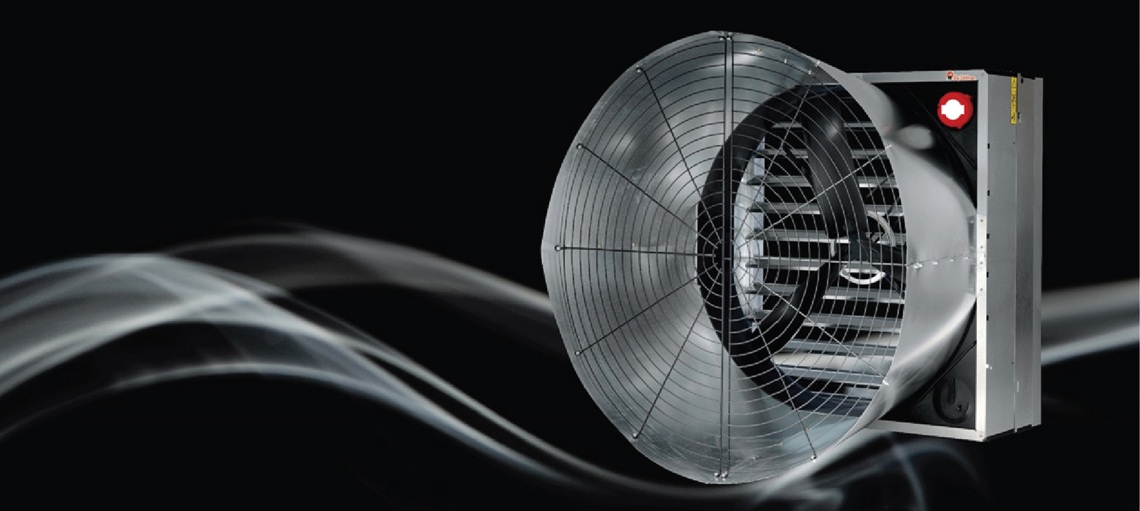

Variable speed ventilation represents the most significant energy-saving opportunity in poultry operations. Big Dutchman's AirMaster EVO series fans are engineered specifically for the Asian market, delivering exceptional performance and energy efficiency with up to 70% energy savings while maintaining uniform airflow even in high-pressure environments up to 110 Pa.

- Energy Savings: Variable speed tunnel fans achieve 46% to 65% power savings across different operational periods

- Pressure Stability: AirMaster EVO fans maintain efficient performance even in high static pressure conditions, ensuring uniform airflow throughout production houses

- Peak Demand Control: Multiple fans at reduced speeds maintain ventilation levels while avoiding costly peak demand charges

- Advanced Integration: Big Dutchman's variable speed fans seamlessly connect with climate control systems for automated operation based on real-time conditions

Q2: Why is insulation crucial in hot and humid climates?

Proper insulation transforms energy-draining buildings into efficient production environments by controlling heat transfer. Big Dutchman's pre-engineered modular buildings are designed specifically for precision livestock farming in Asia's tropical conditions, incorporating region-specific thermal management strategies that reduce cooling loads while maintaining optimal bird environments.

- Heat Reduction: Improved building envelopes achieve up to 33.5% heat gain reduction through strategic insulation placement

- Daily Savings: Proper insulation delivers 9.2 kWh/day electricity savings per housing unit

- Emissions Impact: Average energy costs and CO2 emissions decrease by approximately 40% with optimized building design

- Climate Engineering: Pre-engineered buildings integrate insulation, ventilation, and structural elements for maximum efficiency in Asian climates

Q3: How does digital farm management improve energy efficiency?

Smart farm management systems eliminate the 30.5% energy overuse identified in livestock production through real-time optimization and predictive control. BFN Fusion, Big Dutchman's cloud-based platform, transfers all production and climate data to the cloud in real time through OrbitX gateways, enabling data-driven decisions that reduce risks and optimize efficiency across multiple farm locations.

- Real-Time Integration: BFN Fusion consolidates IoT data from all equipment types, including non-Big Dutchman systems via API connections

- Automated Optimization: Climate curves and algorithms automatically adjust fan speeds, heating, and cooling based on environmental thresholds

- Multi-Farm Management: Centralized platform manages data from all farm locations, feed mills, and production phases in one integrated system

- Predictive Analytics: Advanced algorithms identify patterns and optimization opportunities to minimize energy waste while maintaining optimal conditions

Q4: Can energy-efficient systems improve performance and animal welfare?

Energy efficiency and animal performance work together rather than in competition. Research shows mortality rates dropping from 15% to 3% following proper ventilation upgrades, demonstrating that optimized environmental control systems deliver both energy savings and improved bird health simultaneously.

- Temperature Stability: Reduced fluctuations minimize bird stress and improve feed conversion

- Air Quality: Consistent ventilation maintains optimal respiratory conditions

- Performance Gains: Enhanced thermal comfort leads to better feed conversion ratios

- Welfare Improvement: Animals maintained in optimal conditions without energy waste

Q5: What is the ROI of investing in energy-efficient systems?

Energy efficiency investments typically achieve payback within 3-8 years, with some technologies delivering immediate operational savings. Advanced climate control systems produce poultry with approximately 50% less heating fuel consumption, creating value beyond direct energy savings through improved production metrics.

- Variable Speed Ventilation: 2 to 4-year payback through immediate operational savings

- Building Insulation: 3 to 6-year payback with long-term asset value retention

- Control Systems: 2 to 5-year payback through automation and reduced labour costs

- Integrated Solutions: BFN Fusion, Variable-Speed Fans, and Insulated Buildings create synergistic effects that accelerate returns

Quick Reference: Energy Efficiency Essentials

| Focus Area | Best Practice | Big Dutchman Solution |

| Ventilation Control | Variable-speed, demand-driven fan operation | Variable-Speed Ventilation Fans |

| Building Structure | Climate-appropriate insulation systems | Insulated Poultry Buildings |

| System Integration | Centralized monitoring and automated optimization | BFN Fusion Control Platform |

| Energy Management | Real-time consumption tracking and peak load management | Integrated via BFN Fusion |

Energy efficiency in Asian poultry production requires systematic approaches that address ventilation, building design, and operational management simultaneously. Systems equipped with variable speed fans and heat recovery options are gaining popularity as they help reduce operational costs while maintaining comfortable bird environments.

The combination of proven technologies – variable speed ventilation, optimized building structures, and intelligent control systems – creates measurable improvements in both energy consumption and production performance. With Asia leading global poultry growth, implementing these efficiency measures becomes essential for long-term competitiveness.

References

- Teagasc Agriculture and Food Development Authority. "Energy Efficiency in Poultry Units."

https://teagasc.ie/rural-economy/rural-development/diversification/energy-efficiency-in-poultry-units/ - AgSolar Solutions. "How Much Energy is Your Poultry Farm Using, and Where Is It Going?" December 2024.

https://agsolarsolutions.com/poultry-farm-energy-investigation-energy-go/ - AviNews. "Global poultry meat demand to rise in 2025, Asia leading growth." April 2025.

https://avinews.com/en/global-poultry-meat-demand-to-rise-in-2025-asia-leading-growth/ - University of Georgia Poultry Ventilation. "Variable Speed Tunnel Fans Can Result in Dramatic Power Savings." October 2022. https://www.poultryventilation.com/resources/variable-speed-tunnel-fans-can-result-in-dramatic-power-savings/

- Growth Market Reports. "Poultry Ventilation Fans Market Research Report 2033." August 2025.

https://growthmarketreports.com/report/poultry-ventilation-fans-market - SKOV. "Energy-efficient ventilation in poultry production can save you power, money, and CO2."

https://www.skov.com/en/about-us/knowledge/energy-efficient-ventilation-in-poultry-production-can-save-you-power-money-and-co2/ - ScienceDirect. "Energy saving in agricultural buildings through fan motor control by variable frequency drives." August 2007. https://www.sciencedirect.com/science/article/abs/pii/S0378778807002058

- Canadian Poultry Magazine. "Ventilation Innovations That Deliver Energy Savings." March 2025.

https://www.canadianpoultrymag.com/ventilation-innovation/ - The Poultry Site. "Ventilation boosts poultry productivity."

https://www.thepoultrysite.com/articles/ventilation-boosts-poultry-productivity - Shandong Refull International. "How a Poultry Farm Reduced Mortality Rates with Better Ventilation Systems?" June 2025. https://chinaexhaustfan.com/how-a-poultry-farm-reduced-mortality-rates-with-better-ventilation-systems/

- Oxford Academic. "Comprehensive review on renewable and sustainable heating systems for poultry farming." February 2020. https://academic.oup.com/ijlct/article/15/1/121/5631833

- ScienceDirect. "Application of an artificial neural network to optimise energy inputs." January 2022. https://www.sciencedirect.com/science/article/abs/pii/S036054422200072X

- The Poultry Site. "Hot Weather Management of Poultry."

https://www.thepoultrysite.com/articles/hot-weather-management-of-poultry - U.S. Department of Energy. "Poultry Building Smart Control Technology for Energy Efficiency and Animal Welfare." https://www.energy.gov/eere/buildings/articles/poultry-building-smart-control-technology-energy-efficiency-and-animal

- ScienceDirect. "A study on environmental impact of insulation thickness of poultry building walls." February 2018. https://www.sciencedirect.com/science/article/abs/pii/S0360544218303876

Disclaimer:

This article is based on publicly available research and industry publications and is intended as a general guide for poultry producers. While every effort has been made to ensure accuracy, the information provided should not replace professional veterinary advice or site-specific consultations. Production outcomes may vary based on local conditions, management practices, bird genetics, and other factors.