How to Optimize Broiler Feed Conversion Ratio in Hot and Humid Asian Climates

Broiler producers across Southeast Asia, Southern China, and the Indian subcontinent face mounting challenges from rising temperatures and increasing humidity levels. These environmental stressors significantly impact feed conversion efficiency, directly affecting profitability and bird welfare. This comprehensive guide explores the science behind heat stress impacts on broiler performance and provides evidence-based strategies to optimize feed conversion ratios (FCR) in tropical and subtropical poultry operations.

Understanding these challenges is crucial for maintaining competitive broiler production in Asia's rapidly growing poultry markets, where operational efficiency can determine business success.

Understanding Heat Stress Impact on Feed Conversion Ratio

The Science Behind Performance Decline

Heat stress fundamentally alters broiler physiology and behaviour. A systematic review and meta-analysis found that heat stress significantly increased FCR by 0.17 units (95% CI: 0.04, 0.29) compared to thermoneutral conditions. This increase represents a substantial economic impact when scaled across commercial operations.

Research shows that broilers at 42 days of age exposed to chronic heat stress experienced 32.6% reduced body weight gain, 16.4% lower feed intake, and 25.6% higher feed conversion ratio. These findings highlight the compounding effects of prolonged thermal stress on production efficiency.

Thermoneutral Zone and Critical Thresholds

Optimal broiler performance occurs within the thermoneutral zone, which ranges from 21 to 28°C (70 to 82°F), though this range varies with bird age and production stage. For laying hens, the optimal temperature allowing peak performance is between 19 and 22°C, indicating that mature birds generally require cooler environments for optimal efficiency.

Humidity's Compounding Effect

High relative humidity significantly worsens heat stress impacts. Research demonstrates that non-evaporative heat loss is suppressed by high humidity (>60% RH) at elevated temperatures. This occurs because birds rely heavily on evaporative cooling through panting and respiratory water loss to maintain body temperature.

When ambient humidity exceeds 60%, the effectiveness of these natural cooling mechanisms decreases substantially, forcing birds to reduce feed intake as their primary heat management strategy.

Quantifying Economic Impact in Asian Markets

The financial implications of heat stress are particularly severe in Asian broiler operations. With typical FCR targets around 1.6-1.8 kg feed per kg live weight, an increase of 0.17 units represents:

- Feed cost increase: 9-11% higher feed consumption per kg of meat produced

- Extended production cycles: Reduced daily weight gain extends time to market weight

- Increased mortality risk: Heat stress significantly increased mortality rates (OR = 3.74, 95% CI: 1.39, 10.12)

These factors compound during Asia's hot seasons, typically lasting 4-6 months annually across most tropical regions.

Environmental Management Strategies

The foundation of effective heat stress management lies in creating optimal microclimates within broiler houses through integrated environmental control systems. Successful operations must balance airflow, temperature reduction, and humidity control to maintain bird comfort and performance. These strategies work synergistically to create environments that support optimal feed conversion ratios even during challenging weather conditions.

Advanced Ventilation Systems

- High-velocity air movement: Maintain minimum air speeds of 2.0-2.5 m/s at bird level during hot periods to enhance convective heat loss

- Tunnel ventilation: Create consistent airflow patterns that remove heat and humidity more effectively than cross-ventilation systems

- Variable speed controls: Enable precise adjustment of ventilation rates based on real-time environmental conditions

Evaporative Cooling Technologies

- Cooling pad systems: Reduce incoming air temperature by 5-8°C in moderate humidity conditions (effectiveness decreases above 80% ambient humidity)

- High-pressure fogging: More effective in high-humidity environments through finer water droplets that evaporate readily

- Strategic misting zones: Place near air inlets to maximize cooling efficiency while minimizing water waste

Building Design Optimization

- Reflective roofing materials: White or reflective coatings reduce heat load by 15-20% compared to standard materials

- Proper insulation: Ceiling insulation prevents radiant heat transfer during peak sun hours

- East-west orientation: Minimizes direct sun exposure on building sides during hottest parts of the day

Stocking Density and Management Adaptations

Managing bird density and implementing adaptive management practices becomes crucial during periods of thermal stress, as these factors directly influence the effectiveness of environmental control systems and overall bird welfare. Strategic adjustments to traditional management approaches can significantly improve heat tolerance and maintain production efficiency during challenging periods.

Seasonal Density Adjustments

- Reduce density by 10-15% during hot months to improve air circulation around individual birds

- Enhanced ventilation effectiveness through increased space per bird

- Reduced metabolic heat production by lowering total bird numbers per house

- Improved feed and water access by reducing competition during stress periods

- Balance economic considerations while improving FCR and reducing mortality rates

Strategic Brooding Management

- Early heat conditioning: Gradually expose young chicks to slightly elevated temperatures to improve heat tolerance

- Precise temperature control: Maintain optimal brooding temperatures during first 7-14 days to establish better thermoregulatory capacity

- Foundation for resilience: Early intervention proves more cost-effective than managing severe heat stress in mature birds

Technology Integration and Monitoring

Modern broiler operations increasingly rely on integrated monitoring and control systems that enable proactive management of heat stress conditions rather than reactive responses to performance declines. These technological solutions provide the precision and responsiveness necessary to maintain optimal conditions in challenging climatic environments, transforming data collection into actionable management strategies.

Precision Environmental Control Systems

- Real-time parameter tracking: Continuous monitoring of temperature, humidity, air speed, and bird behaviour indicators

- Automated response capabilities: Pre-programmed adjustments to ventilation, cooling, and feeding schedules based on environmental thresholds

- Predictive algorithms: Anticipate environmental changes based on weather forecasts and historical patterns

- Proactive management: Enable intervention before conditions become problematic rather than reactive responses

Data Analytics and Performance Monitoring

- Historical performance analysis: Identify optimal setpoints for different seasons, bird ages, and production goals

- Environmental correlation: Link FCR data with environmental conditions to identify critical control parameters

- Daily FCR tracking: Enable detection of performance decline within 24-48 hours for rapid intervention

- Predictive modelling: Forecast FCR performance based on planned management changes and weather conditions

Implementation Checklist for Asian Broiler Operations

| Category | Action/Recommendation |

| Environmental Controls | Maintain house temperature between 21-24°C for mature birds |

| Keep relative humidity below 60% during daytime hours | |

| Ensure minimum air speed of 2.0 m/s at bird level during hot periods | |

| Install evaporative cooling systems sized for local climate conditions | |

| Implement reflective roofing and adequate insulation | |

| Management Practices | Reduce stocking density by 10-15% during hot months |

| Adjust feeding schedules to cooler parts of the day | |

| Ensure adequate water space and cool water availability | |

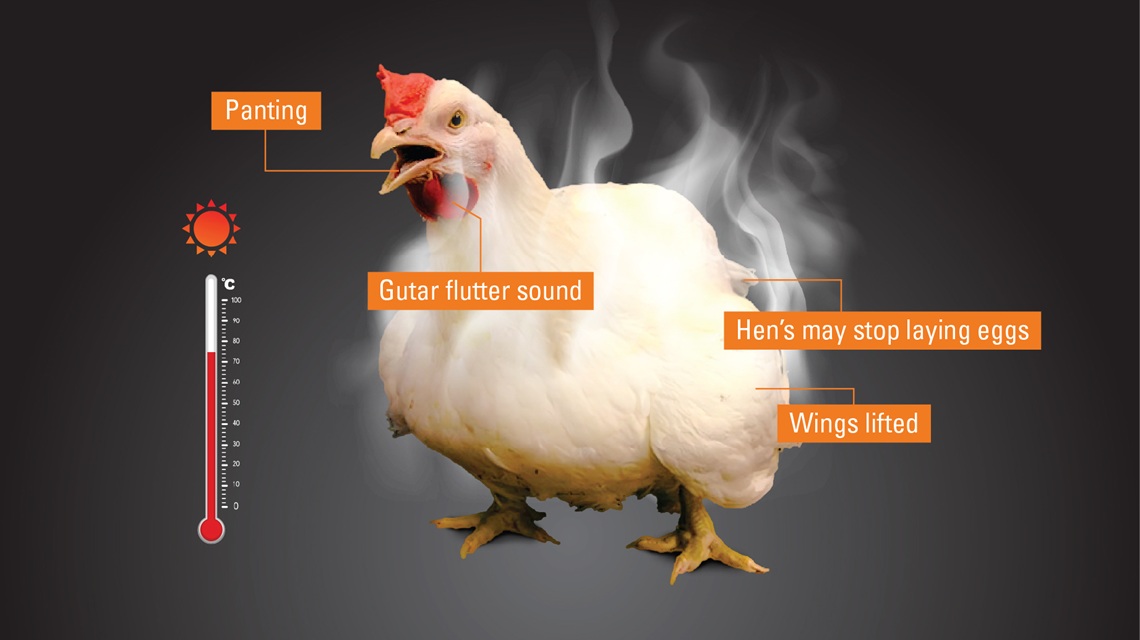

| Monitor bird behaviour for early heat stress indicators | |

| Ensure feed freshness and prevent mycotoxin development | |

| Monitoring and Response | Install automated environmental monitoring systems |

| Establish FCR tracking protocols with daily reporting | |

| Develop emergency response procedures for extreme weather events | |

| Train staff on heat stress recognition and mitigation techniques |

Optimizing broiler feed conversion ratios in hot, humid Asian climates requires a holistic approach that blends environmental controls, management practises, and precision monitoring. Scientific studies reveal that heat stress can raise FCR by at least 0.17 units, underscoring the economic impact on commercial poultry operations. Implementing integrated solutions such as advanced ventilation, evaporative cooling, and proactive management can help counteract the negative effects of heat and humidity on broiler performance.

As the Asian poultry sector expands and faces increasing climate-related challenges, producers who prioritize comprehensive heat stress mitigation measures will sustain their competitive edge. Success depends on viewing heat stress management as a multi-faceted process, involving housing design, environmental regulation and tailored management strategies that address local climate conditions, ultimately supporting efficient production and improved animal welfare.

Frequently Asked Questions

What is the optimal temperature range for broiler chickens in Asian climates?

The thermoneutral zone for broilers ranges from 21 to 28°C (70 to 82°F), though younger birds require temperatures at the higher end of this range. In practice, mature broilers (4+ weeks) perform best at 21-24°C in Asian climates.

How much can heat stress increase feed conversion ratio?

Meta-analysis research shows heat stress increases FCR by an average of 0.17 units compared to optimal conditions. In severe cases, chronic heat stress can increase FCR by 25.6%.

What humidity level should be maintained in broiler houses?

Research indicates that relative humidity above 60% significantly impairs heat loss mechanisms in broilers. Optimal performance occurs when humidity is maintained between 50-60% during the day.

How does heat stress affect broiler mortality?

Heat stress significantly increases mortality risk, with an odds ratio of 3.74 (95% CI: 1.39, 10.12) compared to birds kept in thermoneutral conditions.

What are the most effective cooling strategies for high-humidity environments?

In high-humidity conditions (>70% RH), high-pressure fogging and increased air velocity become more effective than traditional evaporative cooling pads, which lose efficiency as ambient humidity rises.

References

- Heat Stress Meta-Analysis: Liu, L., et al. (2020). Effects of heat stress on body temperature, feed intake, feed conversion efficiency, and plasma biochemical parameters in broiler chickens. Poultry Science, 99(10), 4943-4950. https://www.sciencedirect.com/science/article/pii/S0032579120305209

- Chronic Heat Stress Impact: Zuo, J., et al. (2022). Chronic heat stress affects intestinal barrier function, the expression of tight junction proteins, and mucin protein in broilers. Journal of Applied Poultry Research, 31(1), 100226. https://www.sciencedirect.com/science/article/pii/S1056617121001562

- Thermoneutral Zone Research: Dawkins, M.S., et al. (2004). What makes a good life? A comparison of attitudes of the public and the welfare science community. Animal Welfare, 13(2), 205-210.

https://www.ingentaconnect.com/content/ufaw/aw/2004/00000013/00000002/art00009 - Laying Hen Temperature Optimization: Mack, L.A., et al. (2013). Genetic parameter estimates for feed intake, residual feed intake, and production traits in laying hens. Poultry Science, 92(10), 2766-2775.

https://academic.oup.com/ps/article/92/10/2766/1522641 - Humidity and Heat Loss: Lu, Q., et al. (2007). Heat stress in broiler chickens and the effect of dietary betaine. Asian-Australasian Journal of Animal Sciences, 20(5), 692-701.

https://www.ajas.info/journal/view.php?doi=10.5713/ajas.2007.692 - Mortality Risk Analysis: Mashaly, M.M., et al. (2004). Effect of heat stress on production parameters and immune responses of commercial laying hens. Poultry Science, 83(6), 889-894.

https://academic.oup.com/ps/article/83/6/889/1522486

Disclaimer:

This article is based on publicly available research and industry publications and is intended as a general guide for poultry producers. While every effort has been made to ensure accuracy, the information provided should not replace professional veterinary advice or site-specific consultations. Production outcomes may vary based on local conditions, management practices, bird genetics, and other factors.