Digital EggFlow: The Smartest and Fastest Way to Sort Eggs

Egg collection is one of the most critical aspects of running a successful layer farm, especially with increasing demands for efficiency, profitability, and biosecurity. Enter Digital EggFlow, an advanced system developed by Big Dutchman, designed to streamline egg collection processes. By incorporating automation and digital management, the EggFlow system addresses key challenges in egg collection while offering significant time and cost savings. Let’s explore how this system works and why it is transforming modern layer farming.

What is the Digital EggFlow System?

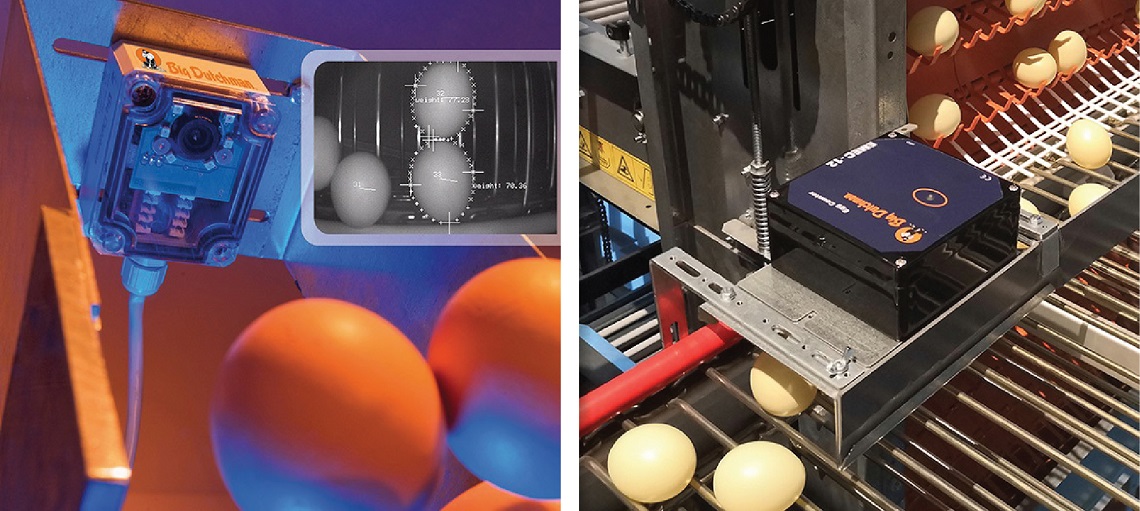

The Digital EggFlow system is an innovative egg collection solution that integrates automation, digital visualisation, and smart control. It includes components such as cross conveyors, graders, sensors, and digital interfaces that provide real-time insights into the egg collection process. By creating a "digital twin" of the egg flow, the system ensures precise monitoring and management from individual houses to the central packing station.

Unlike traditional manual or semi-automated systems, Digital EggFlow optimises efficiency, minimises egg breakages, and enhances farm management, making it an essential tool for modern layer farm operations.

Challenges in Traditional Egg Collection

Before diving into the advantages of EggFlow, it’s important to understand the challenges layer farms face with conventional egg collection systems:

1. Underutilised Equipment

Many farms invest in costly graders and dosing tables, but these machines often operate below capacity. This results in high running costs without maximising returns.

2. Overwhelmed Systems During Peak Collection Hours

During peak laying periods, the influx of eggs often exceeds the system’s capacity, leading to jams, inefficiencies, and delays.

3. Egg Breakages and Contamination Risks

Broken eggs not only lead to product loss but also pose biosecurity concerns. A single broken egg can contaminate up to 80 additional eggs, raising risks of diseases like Salmonella.

4. DIY Solutions Leading to Inefficiencies

Farmers often resort to self-made systems to manage egg collection challenges. While inventive, these solutions can increase egg pressure on belts, causing more breakages.

5. High Operating Costs

Some farms use multiple conveyors in a single house to handle egg flow, leading to increased energy consumption, maintenance needs, and spare part costs.

How the Digital EggFlow System Solves These Problems

Digital EggFlow addresses these issues through its smart and automated features:

1. Real-Time Digital Management

The system creates a visual representation of the egg flow, allowing farm managers to monitor everything in real time. Sensors track the number of eggs collected, the belt speed, and pressure levels, ensuring smooth and efficient operation.

2. Automated Egg Collection

EggFlow automates the collection process based on predefined schedules. It groups houses for optimised collection and ensures that no belts are overfilled, reducing egg jams and breakages.

3. Stepless Egg Flow Control

Stepless egg flow control is one of the standout features. By adjusting belt speeds and pressure dynamically, the system minimises cracks and ensures eggs reach the grading machine in perfect condition.

4. Precise Egg Counting

The system uses advanced camera-based counters for accurate tracking. This data helps managers assess performance at the house, row, or even tier level, enabling informed decision-making.

Advantages of the Digital EggFlow System

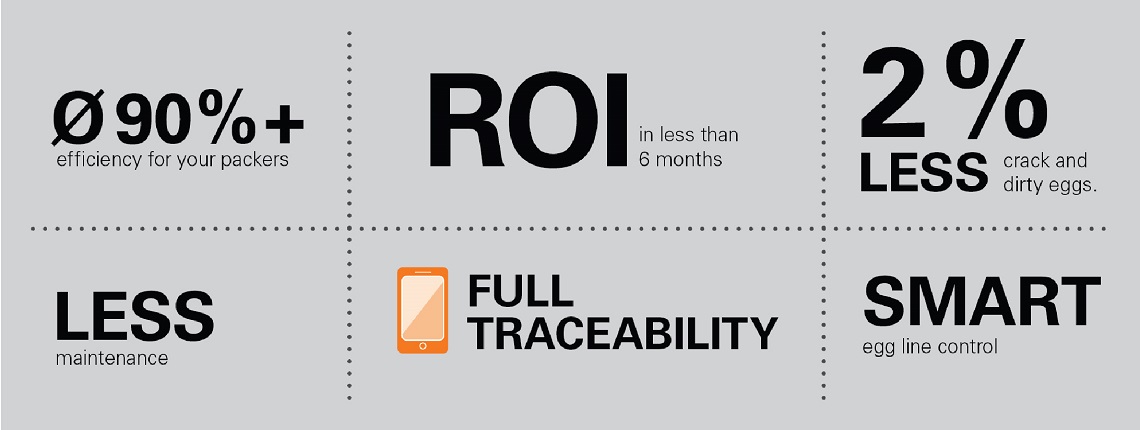

The EggFlow system delivers numerous benefits for farms of all sizes:

1. Time Savings and Efficiency

Time is money, and EggFlow saves plenty of both. Farms using the system report up to a 35% reduction in egg collection time. For example, a farm with 1.25 million layers reduced its collection time from 11 hours to just 7–8 hours.

2. Reduced Breakages and Improved Biosecurity

By optimising egg flow, EggFlow significantly reduces breakages. The smooth operation prevents cracks and contamination, safeguarding food safety and reducing waste.

3. Cost Savings

EggFlow reduces costs in multiple ways:

• Lower labour requirements through automation

• Reduced energy usage by optimising conveyor operations

• Minimised maintenance and spare part expenses

These savings make the system highly cost-effective, with a return on investment achievable in under a year for many farms.

4. Worker Productivity

Simplified operations mean workers can focus on higher-value tasks. Automation reduces the need for specialised skills, which is especially important given the labour shortages in egg production today.

5. Flexibility for Egg Collection Groups

EggFlow allows for customised collection. For instance, farms producing different egg types—like omega-3, brown, or white eggs—can collect and process them separately without disrupting operations.

6. Handling High Concentrations of Eggs

During peak laying periods, EggFlow efficiently handles high concentrations of eggs, ensuring smooth transport from the nest to the packing station.

Success Stories: Real Results with EggFlow

Farmers worldwide have experienced remarkable improvements after adopting Digital EggFlow. Here are a few examples:

1. Large-Scale Operation in China

A farm with over 3 million layers reported a grading efficiency of 95.5% after installing EggFlow. The system’s reliability and precision were game changers for the operation.

2. Standalone System in an 8-House Farm

This farm reduced egg collection time by 35%, handling 1.25 million layers more efficiently.

3. Automated System for 1.8 Million Layers

A farm in Europe requested a solution to collect eggs within 8 hours. EggFlow achieved this while maintaining a grading efficiency of over 92%.

4. Family-Owned Barn Production in Germany

Despite having only two workers, this farm uses EggFlow to manage 42,000 layers in barn production and a packing capacity of 30,000 eggs per hour, showcasing the system's suitability even for smaller operations.

The Digital EggFlow system is revolutionising egg collection in layer farms by addressing long-standing challenges. Its ability to save time, reduce costs, enhance biosecurity, and improve efficiency means it’s a must-have for modern poultry operations. Whether you’re running a small family farm or managing millions of layers, EggFlow provides a scalable solution tailored to your needs.

Learn more by watching the Big Spotlight series video on Digital Egg Flow.

Ask us about how Digital EggFlow can enhance egg collection in your layer farm. Click the ‘Send a Message’ Button below to talk to us.