Crisis Response: Strategies for Post-Outbreak Recovery & Egg Security

Disease outbreaks like avian influenza and supply shocks are increasingly disrupting global egg production. In 2024–25, Australia lost nearly 7 percent of its national egg-laying flock that amounted to over 2 million hens due to High Pathogenic Avian Influenza (HPAI). The result: supermarket rationing, price hikes of up to 11.5 percent, and a crisis that underscored how unprepared the industry was for disruption.

The lesson is clear: crisis recovery must go beyond simply restarting production. It requires a full redesign of systems to embed resilience at every layer farm, from infrastructure to intelligence.

When a crisis hits, its visible effects are swift and painful. But what often determines the depth of damage is the unseen fragility built into systems optimized only for normal operations.

The Hidden Weakness in Current Feed Systems

During the Australian crisis, producers with outdated or manual systems took weeks longer to recover. Delays in restocking, disinfection, and approvals revealed five systemic vulnerabilities:

- Centralized, non-modular systems made it impossible to isolate and preserve clean zones.

- Labor-intensive operations struggled when movement restrictions and staff shortages occurred.

- Lack of digital oversight meant farms couldn’t act on real-time data or automate essential controls.

- Weak biosecurity layouts accelerated contamination via air, water, and equipment flow.

- Poor traceability delayed inspections, insurance claims, and re-entry approvals.

These are not merely logistical issues. They are strategic weaknesses that compromise business continuity. Recovery today must be reframed: not just restoring what was lost, but redesigning for adaptability and endurance.

A Resilience Roadmap for Crisis Recovery

Here is a strategic framework that combines infrastructure, automation, and traceability to help farms recover quickly and rebuild smarter.

1. Modular & Scalable Infrastructure

Big Dutchman’s turnkey modular housing supports faster restocking, cleaning, and isolation. These structures allow zone-based response, helping producers contain outbreaks without losing full production.

2. Biosecurity-Centric Design

Recovery is an opportunity to rebuild better. Farms can implement clean/dirty workflows, vehicle disinfection lanes, and air filtration systems like Pollo-L. These upgrades help meet modern biosecurity expectations while restoring consumer and regulator confidence.

3. Digital Control & Automation

ViperTouch and BFN Fusion enable remote monitoring and control of climate, feed, and biosecurity. These tools reduce physical labour exposure, log operational data for audits, and maintain continuity under restricted movement.

4. Pre-Crisis Preparedness & Traceability

Real-time and historical data from Big Dutchman systems provide the foundation for faster audits, root-cause analysis, and informed crisis planning. The more traceable your farm, the faster you return to market.

5. System Redundancy for Layer Houses

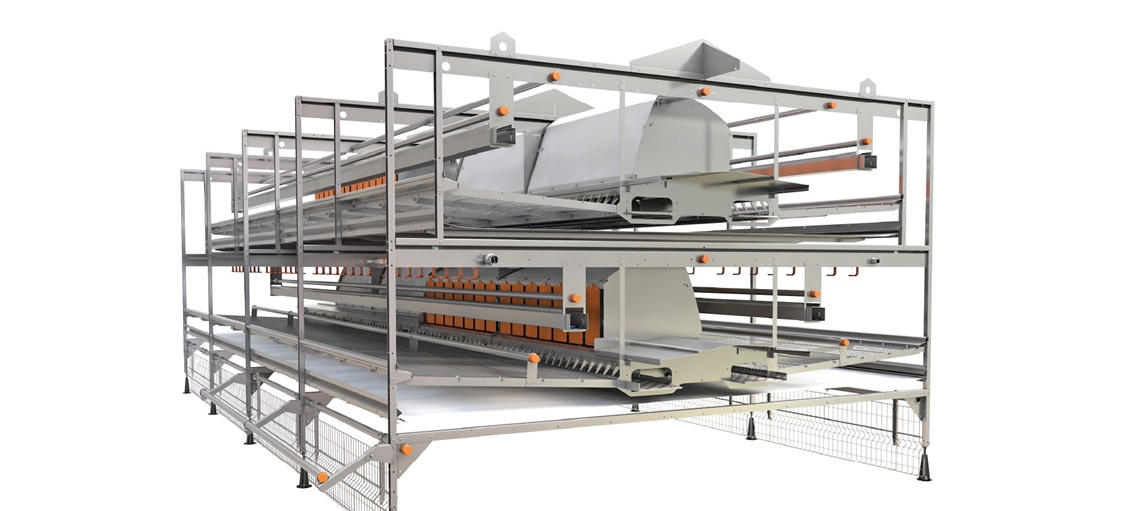

Backup power, water, and ventilation systems ensure operation even under duress. Layer systems such as NATURA Visio offer rearing flexibility and can support phased repopulation under varying protocols.

6. Smart Feeding & Reintroduction

Tools like MultiVacc enable rapid and uniform vaccination during restocking. Automated feeding systems reduce manual input while maintaining flock nutrition and health through transitions.

7. Environmental Rehabilitation

Systems like OptiSec, OptiPlate, and CompoTower process infected litter into safe, stabilized compost. This helps accelerate site recovery, reduce odour, and meet local environmental regulations.

Preparedness is Profit Protection

Below is a practical checklist to guide farms in strengthening crisis readiness.

| Preparedness Area | Action Steps | Why It Matters |

Modular Infrastructure |

Use zone-isolatable housing with separate ventilation systems. | Limits disease spread and enables faster recovery per zone. |

Biosecurity Layouts |

Implement shower entries, disinfection tunnels, and vehicle wash bays. | Reduces pathogen entry risk and increases audit pass rates. |

Remote Monitoring Systems |

Deploy ViperTouch and BFN Fusion to automate alerts, control systems, and log data continuously. | Supports no-contact operation and traceable compliance. |

Traceability Framework |

Digitally log feed, mortality, water, and temperature by flock or house. | Speeds up restocking and supports faster insurance and authority approval. |

Staff SOPs |

Develop crisis roles, PPE stockpiles, and training for bio-containment and remote workflows. | Minimizes delays during staff disruptions. |

Emergency Contact Tree |

Maintain up-to-date directory of authorities, suppliers, and service partners. | Improves coordination and emergency response time. |

Input Resilience |

Stock key feed materials and automate silo monitoring. | Ensures uninterrupted nutrition and reduces exposure to last-minute price surges. |

Utility Redundancies |

Ensure backup power, water, and climate systems are available and routinely tested. | Keeps essentials running when grid or supply is down. |

Repopulation Tools |

Use MultiVacc and smart feeding for flock reintroduction. | Minimizes stress, improves uniformity, and supports fast productivity recovery. |

Environmental Controls |

Integrate OptiSec, OptiPlate, and CompoTower for litter processing and site rehabilitation. | Reduces ecological load and helps pass sanitation and emission standards. |

Resilience is Strategy

Crisis is no longer a rare event. For poultry producers in Asia, it is now a strategic consideration as one that determines whether an operation remains viable in the face of disruption.

The key is integration. Modular housing, traceable biosecurity, smart environmental control, enhanced reintroduction protocols, and intelligent data systems must function together. Big Dutchman’s ecosystem, anchored by BFN Fusion and ViperTouch, offers more than a recovery strategy. It delivers the foundation for resilient, sustainable poultry farming in the decade ahead.

Preparedness is not an overhead. It is a competitive advantage and an investment in tomorrow.