ActiWel Mini: Smart, Welfare-focused Farrowing Pen for Modern Pig Production

Across the Asia-Pacific region, pig farmers are facing new challenges. Market expectations are shifting, and there’s a growing interest in animal welfare from both consumers and supply chain partners. But unlike in the European Union, most Asian countries don’t yet enforce strict animal welfare legislation, leaving producers to strike their own balance between welfare improvements and operational efficiency.

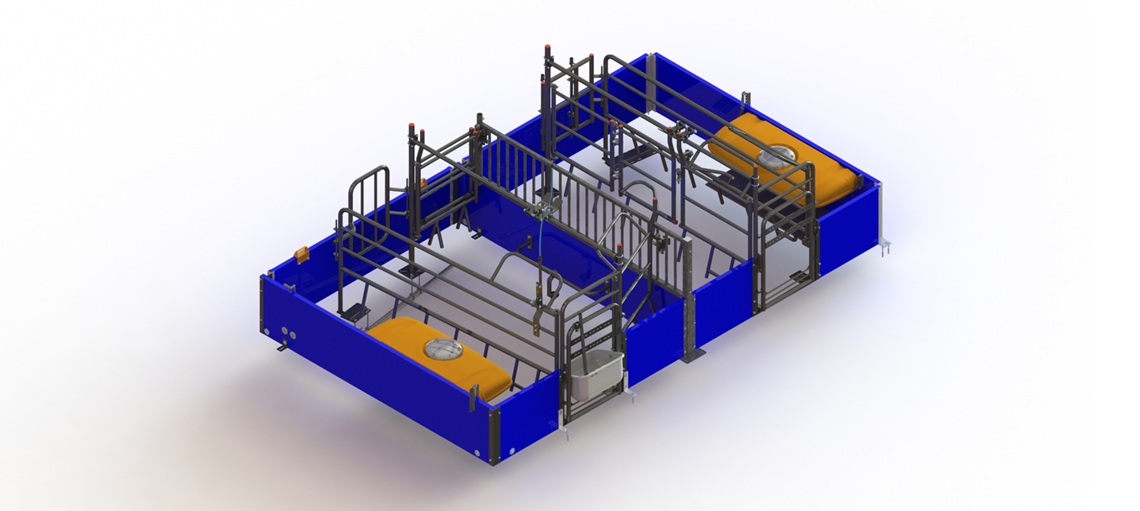

That’s where the ActiWel Mini brings the advantage. Developed by Big Dutchman, this compact farrowing crate was specifically designed for cost-conscious markets. It helps producers meet welfare expectations, improve piglet safety, and optimise space, all without the high costs typically associated with welfare-compliant systems.

Whether you're upgrading your existing facilities or planning a new build, the ActiWel Mini offers a forward-looking solution that’s both practical and affordable.

Why ActiWel Mini Makes Economic Sense

In today’s production environment, every square meter counts. The ActiWel Mini has been engineered with space efficiency in mind. Its smaller footprint at just 2.0 x 2.4 meters translates to a 20% reduction in building space compared to traditional welfare crates. This alone can deliver significant cost savings, particularly in large-scale operations.

At the same time, crate construction costs are also lower. The ActiWel Mini can cut capital spending by up to 15%, making it a far more accessible option for producers who want to modernise their systems without major financial strain.

Importantly, these savings don’t come at the cost of animal welfare or piglet performance. The ActiWel Mini is designed to support sow mobility, reduce piglet losses, and maintain efficient farrowing management—ensuring the investment pays off in productivity.

Practical Benefits Built for Real Farms

Each feature of the ActiWel Mini was developed with real-world farm operations in mind. Here’s how it delivers where it matters most:

- Lower Investment, Same High Standards

Save up to 15% on crate costs compared to traditional systems, making it easier to meet welfare goals without blowing the budget. - Space-Saving Design

Its 2.0 x 2.4 m layout reduces building space by over 20%, allowing more pens per barn or a smaller total construction footprint. - Freedom for the Sow

The crate opens wide enough for the sow to turn freely—a key animal welfare indicator—while allowing full confinement when needed. - Built-In Piglet Protection

Specially designed side frames and piglet escape zones reduce the risk of crushing, improving survival rates with minimal intervention. - Farrowing Made Easier

The double foldable front door ensures fast, easy access to the sow during farrowing, reducing stress on both animals and handlers. - Cleaner, Faster, Smarter Handling

Corner-less surfaces and lightweight construction make daily cleaning easier and handling more efficient, reducing labour strain.

Engineered for Flexibility and Function

The ActiWel Mini isn’t just a stripped-down version of a larger crate—it’s been carefully optimised for farms that need performance in tight spaces. Here are the key technical specifications that support its practical use:

- Crate Area Options:

- 2.63 m² with standard back door

- 3.10 m² with optional extendable back door

- Pen Compatibility:

- Standard layout: 2.0 x 2.4 m

- Also adaptable to 1.8 m wide pens with optional narrow piglet cover

- Smart Locking Systems:

- Adjustable snap locks for quick and precise installation

- Front and rear pin locks positioned for better ergonomics

- Door Configurations:

- Double foldable front door with one-handed operation

- Options for anti-lying bars and CS feeder front doors

- Extendable or standard back doors available

- Piglet Cover Options:

- Orange plastic piglet cover for 2.0 m pens

- Galvanized narrow cover for 1.8 m pens

- Flooring Flexibility:

- Fully plastic slats or a plastic/cast-iron slat combination to suit different climate and hygiene needs

- Penning Layouts Available:

- Fully enclosed PVC farrowing pens

- Side-top opening pens

- Fully front-opening configurations

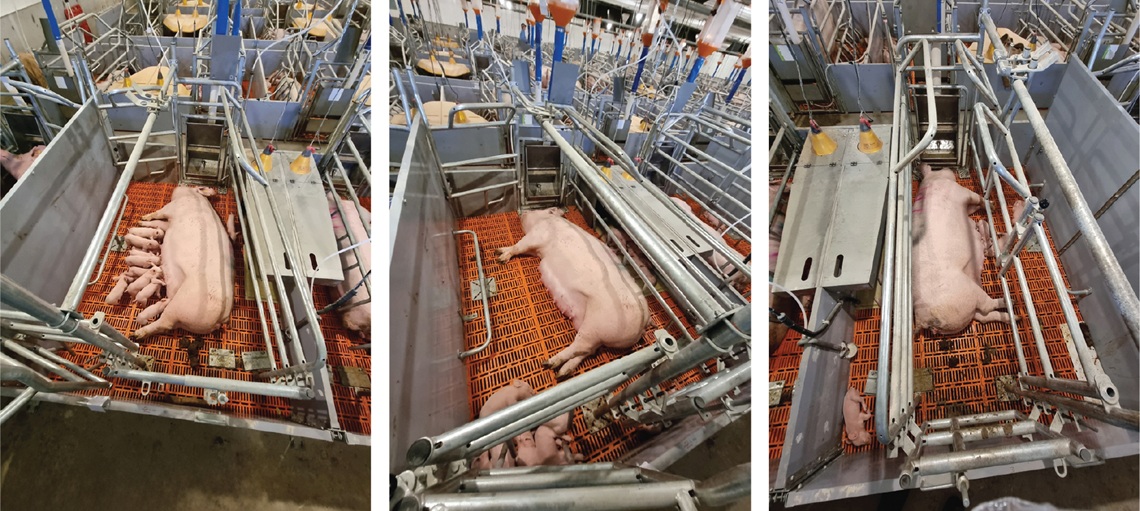

Field-Tested Performance

In 2022, ActiWel Mini crates were installed and tested on commercial farms in Australia. Using pens sized 1.8 x 2.4 m, the tests measured piglet mortality rates under different crate opening conditions.

- Opened on Day 3: Piglet mortality averaged around 12%, largely due to weak mobility in very young piglets unable to avoid the sow.

- Opened on Day 7: Mortality dropped to between 5–10%, showing that a simple adjustment in management can lead to piglet survival rates comparable to confined crates.

Based on these results, Big Dutchman recommends opening the crate at Day 7, striking a balance between sow freedom and piglet safety.

Supporting Better Outcomes Without the High Cost

Animal welfare isn’t just about compliance—it’s also about performance. Reducing stress in sows can lead to better milk production, smoother farrowing, and calmer behaviour. At the same time, lowering piglet losses directly impacts litter productivity, improving profitability over the long term.

With the ActiWel Mini, producers get access to these benefits without needing to redesign their entire operation or invest in costly infrastructure. Its retrofit-ready dimensions and modular options make it suitable for a wide range of barn setups, whether you’re adapting older facilities or building from the ground up.

The ActiWel Mini is more than a crate, it's a strategic upgrade. It gives pig producers across Asia a reliable, welfare-friendly, and cost-effective solution that supports better animal outcomes and long-term farm success.

As welfare expectations continue to evolve, staying ahead doesn’t have to mean spending more. ActiWel Mini now allows you to make a smarter investment that supports your animals, your business, and your future.

Learn more about Actiwel Mini.