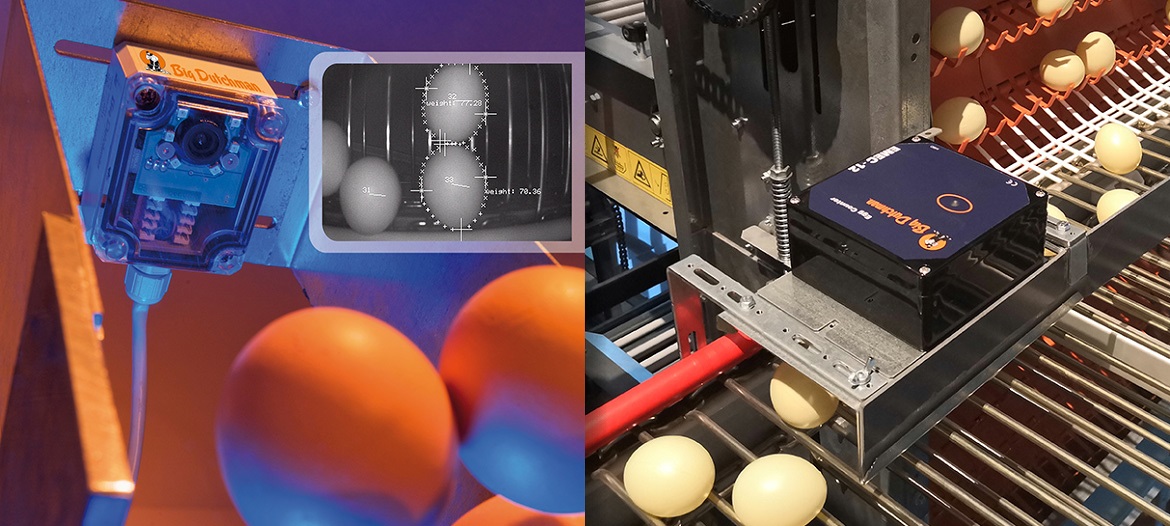

Accurate counting system

EggCam uses a camera technology combined with image processing, which is integrated in the sensor. The camera helps in the high-resolution monitoring of each egg closely that passes through the conveying path. It can either be installed at the cross belt or the longitudinal egg belt in each tier.

Advantages

- Can work in the dark

- The count data is easy to access and analyse

- Offers accurate monitoring of eggs